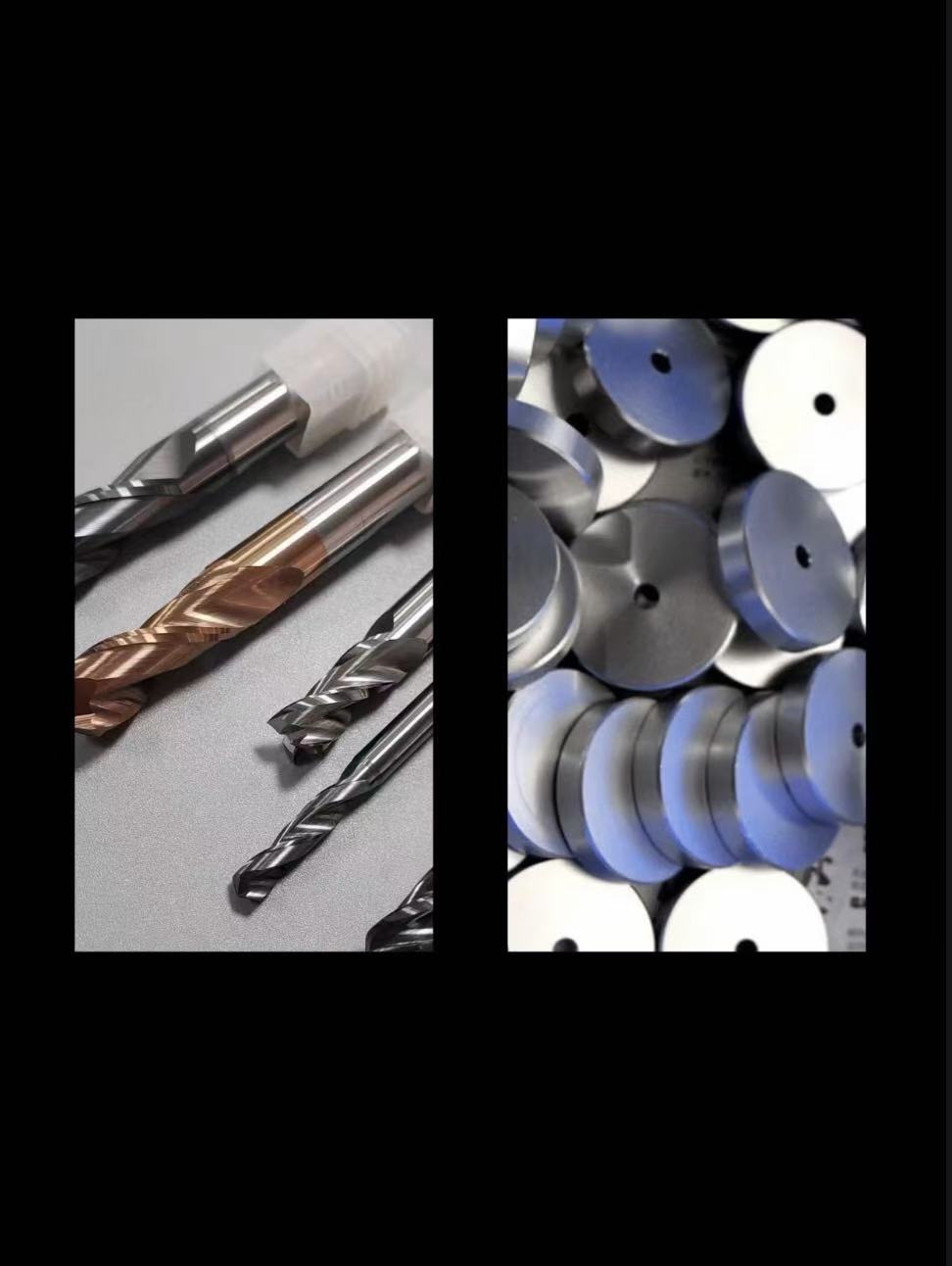

Tungsten steel milling cutter vs High speed steel milling cutter

يشارك

- The main difference between tungsten steel milling cutter and high speed steel milling cutter lies in the different raw materials and manufacturing process they use.

Material difference:

The raw material used for tungsten steel milling cutter is tungsten carbide, which is often called tungsten steel. This material has a very high hardness and wear resistance, and can maintain stable performance at high temperatures.

The raw material used for high-speed steel milling cutter is high-speed steel. High-speed steel is a special alloy steel, containing a large number of tungsten, molybdenum, chromium, vanadium and other elements, these elements can improve the hardness and wear resistance of steel.

Performance difference:

Tungsten steel milling cutters have higher hardness and wear resistance due to the use of tungsten carbide material, which makes them suitable for machining materials with higher hardness.

Although the hardness and wear resistance of HSS milling cutter is not as good as tungsten steel milling cutter, but its toughness and impact resistance performance is better, suitable for processing some more complex shapes and materials.

- In summary, tungsten steel milling cutter and high-speed steel milling cutter have their own advantages and applicable processing occasions, the choice of which milling cutter should be based on specific processing needs to decide.